Sustainable Plastic Packaging

- Student

- Rob Piscatelli

- College(s)

- Mendoza College of Business

- Faculty Advisor

- Sam Miller

- Class Year

- 2013

Plastic packaging is used in almost all consumer goods and is therefore a part of everyday life. Plastic packaging is necessary to protect the product throughout the shipping process however, it is costly and wasteful. As producers are becoming more aware of the green movement and advancements are made in packaging technology the future of plastic packaging will likely become eco-efficient and eco-effective.

The Question: Will packaging become more sustainable in the future?

If companies find that new and sustainable packaging materials are cheaper or more functional, they will likely implement more sustainable packaging.

Sustainable Plastic Packaging System

Sustainable Plastic Packaging System

The Packaging System

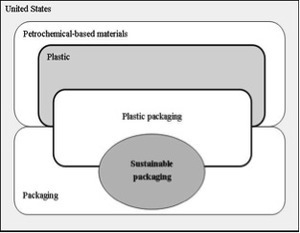

Plastic packaging requires the participation of several companies that produce the raw materials to package goods. There are two major systems at work in the plastic packaging process: packaging and petrochemicals, the chemicals used to produce plastics. The packaging industry is made of more than just plastic packaging, but this is the most unsustainable type of packaging since it consumes about 121 barrels of oil to produce one ton of plastic. Heading toward sustainable packaging may force a larger use of non-plastic materials.

Ways Packaging Can be Sustainable

- Eco-efficiency: What most companies strive for currently. It is “doing more with less” (McDonough & Braungart, 2001, p. 66). Eco-efficiency reduces the materials used in production and therefore reduces costs and waste. For example, reducing the amount of plastic used in Poland Springs water bottles over time is eco-efficiency.

- Eco-effectiveness: Eco-effectiveness must “after each useful life, provide nourishment for something new” (McDonough & Braungart, 2001, p. 70). Often times when a product is recycled it is more accurately down-cycled; it is reproduced into a new product that is much cruder. Manufacturers must mimic the way nature completely breaks down and reuses everything in its cycle. Striving toward eco-efficiency is moving toward modifying the process and inputs in plastic packaging to make it more sustainable.

Current Packaging Innovations

- Nestle decreased the PET plastic in their Poland Spring Eco-Shape water bottles by 60% over a 15 year period. Nestles estimates it has saved over 260 million pounds of plastic.

- Pepsi developed their 100% green bottle made from bio-based raw materials such as switch grass, pine bark, and corn husks.

- Coca-Cola developed a 30% green bottle. While more expensive than petroleum, this is expected to change in the near future due to rising oil prices.

- Ecovative produces mushroom based packaging that is 100% biodegradable is made up of natural agricultural waste like rice hulls, cotton burs, and mycelium, the roots of mushrooms. This packaging does not produce any waste in landfills while still matching plastic in insulation, fire resistance, moisture resistance, and vapor resistance.

Looking to the Future

For plastic packaging to become truly sustainable, large companies taking charge and demanding sustainable packaging will put the pressure on to develop the methods. Companies such as Target and Wal-Mart are already looking toward sustainable packaging methods to reduce waste and increase renewable content.

In the future, other major retailers will most likely follow similarly as the pressure to be eco-effective increases, and more companies take steps in the sustainable packaging direction.